The hourly output is higher than that of the 480D type impact crusher.

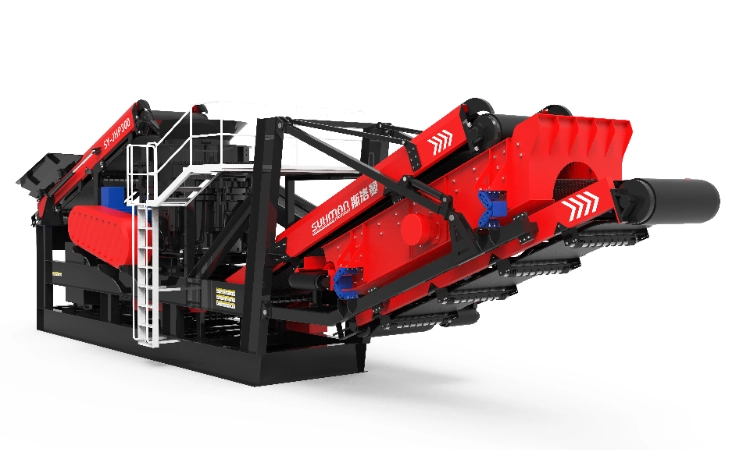

The stability of the tracked mobile impact crusher is excellent. It adopts a tracked all steel ship structure with high strength, low grounding ratio, and can adapt to complex terrain. The high torque walking motor technology is mature, with strong driving force and high reliability. The walking system adopts a hydraulic system with full power variable starting, which has excellent performance and can fully utilize the power of the generator. During crushing operations, even in the face of significant impact and shaking forces, stable operation can be maintained, reducing equipment failures and maintenance costs. For example, in harsh working environments such as mines, it can stably carry out crushing operations without being affected by terrain and working conditions.

Working Principle

Application

The tracked mobile impact crusher plant has a wide range of adaptability to materials. It can crush various materials such as construction waste, bluestone, slag, quartz sand, limestone, quartz stone, etc. Whether in mining, construction waste recycling, or road construction, it can play an excellent role in crushing. For example, in construction waste recycling, it can crush discarded concrete, bricks, etc. into reusable aggregates; In road construction, various natural stone materials can be processed to provide high-quality materials for road paving.

Video Presentation

Product Parameter

| Project | Name | SF-580D |

| Feed section | Feeding capacity (t/h) | 300 |

| Hopper volume (m³) | 6 | |

| Power (kw) | 4.5×2 | |

| Feeder size (length x width) (mm) | 3950x1460 | |

| Feeding height (mm) | 3850 | |

| Crusher | Crusher model | 1315 |

| Feed inlet size (length x width) (mm) | 1540x1100 | |

| Maximum feed particle size (mm) | <700 | |

| Adjustment range of discharge port (mm) | 300-500\0-150 | |

| Crusher weight (t) | 23 | |

| Crusher power (kw) | 315 | |

| Main belt | Length x Width (mm) | 11300×1600 |

| Unloading height (mm) | 3250 | |

| Power (kw) | 9.5×2 | |

| Belt for finished materials | Length x Width (mm) | 5200×1350 |

| Unloading height (mm) | 2860 | |

| Power (kw) | 7.2×2 | |

| Return material hanging sieve | Length x Width (mm) | 4600×2160 |

| Power (kw) | 3.7×2 | |

| Number of sieve layers (layers) | 1 | |

| Screen size (mm) | 4000×1540 | |

| Transition belt | Length x Width (mm) | 1750×970 |

| Power (kw) | 3 | |

| Return conveyer belt | Length x Width (mm) | 7200×970 |

| Power (kw) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (kw) | 3 | |

| Complete machine | Track chassis model | LDZ55-3657 |

| Engine power (kw) | 100 | |

| Whole machine weight (t) | 53 | |

| Machine processing capacity (t/h) | 180-230 | |

| Total power of crushing work (kw) | 378.1 | |

| Working dimensions (length, width, height/mm) | 15932×3700×4100 | |

| Transportation dimensions (length, width, height/mm) | 15932×3500×3900 |

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)

.png)

.png)